- HOME

- Products

- All aluminum home CNC equipment

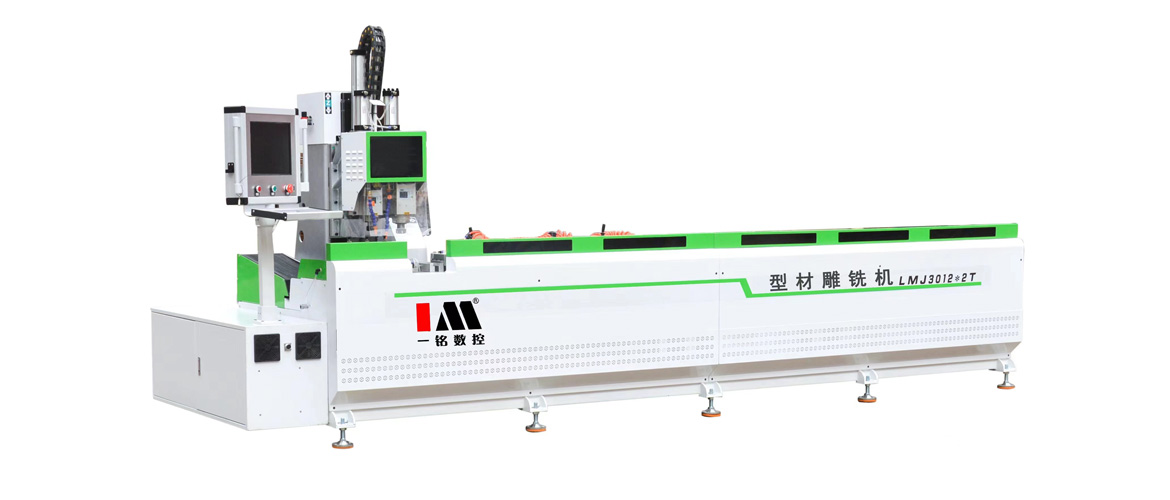

- YM Profile Engraving and Milling Machine (Type A)

YM Profile Engraving and Milling Machine (Type A)

Functional characteristics

NO. | performance index | performance index | parameter |

1 | stroke | X stroke | 3000mm |

? | ? | Y stroke | 120mm |

? | ? | Z stroke | 200mm |

2 | Dimensions | ? | 4800*1500*2000mm |

3 | Precision | Precision | 0.1mm |

? | ? | Repeatability | 0.1mm |

4 | structure | Countertop structure | High strength aluminum profiles |

? | ? | structure | Y/Z lead screw, X rack |

5 | speed | Maximum empty travel speed | 100000mm/min |

? | ? | Working speed | 30000mm/min |

6 | Spindle power | T1 | 6.0KW |

? | ? | T2 | 2.2KW |

7 | Operating mode | ? | servo |

8 | Operating Voltage | ? | AC380V/50Hz |

9 | Run command | ? | G-code |

10 | operating system | ? | Yiming System |

11 | net weight | ? | 1800Kg |

?

Simple operation and detailed display

1.Operating system: Yiming customized system (programming free, modular parameters)

2. Motor and driver: Imported AC servo (X-axis 1000w Y-axis 1500w Z-axis 1000w)

3. Spindle motor: 6.0kw * 1 unit 2.2kw * 1 unit

4. Frequency converter: 7.5kw/380v * 1 set 2.2kw/380v * 1 set

5. Guide rail: straight square rail imported from Taiwan, high dustproof and lubrication free slide rail

6.Transmission mode: X-axis rack, Y-axis, Z-axis ball screw imported from Taiwan

7.Bed structure: rectangular steel pipe welding, cast aluminum head structure

8. Dust prevention treatment: Organ paper shield to effectively avoid dust and debris; Protective guide rail and lead screw

9. Main electrical components: Schneider

10. Cable: special cable for supporting chain

11. Lubrication: Automatic oil injection pump is used to regularly supply oil to each lubrication point

Product video introduction

YM Profile Engraving and Milling Machine (Type A)

◆ YM Intelligent Profile Processing Center, equipped with industry-leading components.

◆ Adopt air-cooled electric spindle, and the drive system adopts imported high-power servo motor.

◆ Taiwan Yiming customized system, modular parameters, foolproof operation, simple and easy to use.

◆ CNC digital control, with breakpoint memory function, ensures continuous operation in the event of accidental (knife breakage) or the next day.

◆ Overall structural welding, tempering and aging treatment, firm and not deformed. X-Z main casting structure, strong cutting force, higher accuracy

Cut sample

◆ Minimal doors, ecological doors and other furniture industries, profile processing.

◆ Mechanical processing industry: processing of soft metals such as copper and aluminum.

◆ Profile products: audio, game cabinets, computer tables, sewing machine tables, musical instruments.