- HOME

- Products

- Panel furniture production line

- TM248F-2 automatic vacuum laminating machine

TM248F-2 automatic vacuum laminating machine

Functional characteristics

This equipment can be used for three-dimensional pasting of various PVC films on various materials such as furniture, cabinets, speakers, and paint-free doors. After installing the silica gel board, it is used for the heat transfer film and single-sided solid wood veneer.

Simple operation and detailed display

http://yiming.winbrand.cc/

The equipment is made of high-quality steel, can withstand a variety of harsh transportation conditions, and has high stability without deformation

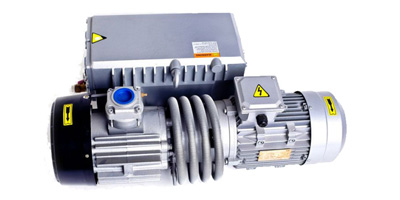

Vacuum pump

The vacuum pump adopts German technology and domestically manufactured high-quality direct-connected pumps. Low noise, no pollution, long life

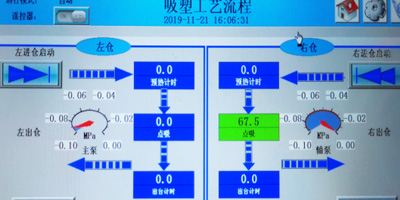

The control system adopts touch screen PLC digital control system

The control system adopts a touch screen PLC digital control system, which can be automatically controlled according to temperature changes, thereby adjusting the heating temperature to achieve the purpose of precise temperature control; 16 sets of formulas are stored to respond to various environmental changes at any time; working status man-machine dialogue, real-time display Current status; fault alarm, clear at a glance; real-time display of working status, clear and clear work flow; manual and automatic switching at will, working conditions are under control

Workbench

Heating at the bottom of the workbench can effectively reduce the preheating time of the cold table and the temperature of the PVC film corners when the cold table is working is not enough, resulting in degumming; heating on both sides effectively reduces the deformation of the door panel

Walking system

The walking system adopts frequency conversion rack drive, which reduces the speed when approaching the heating chamber to prevent displacement of the workpiece backing

Dual airway

Double air passages, double air tanks, uniform adsorption and stable pressure, effectively improving the service life of the vacuum pump;

Product video introduction

TM248F-2 automatic vacuum laminating machine

It is mainly suitable for coating various cabinet door panels, wooden door coating, sliding door coating, soft bag decoration leather coating and other materials and equipment used for coating PVC, veneer, decorative paper, etc. on all sides. Various PVC films can be pasted on Furniture, cabinets, sound boxes, craft doors, decorative wall skirting boards and other board furniture, and can be used for heat transfer film and single-sided veneer after installing silica gel board.

Equipment technical parameters

project | specification |

Dimensions | 10800×2000×1600mm (length, width and height) |

working desk size | 2500×1100/1300mm (inner diameter) |

Maximum processing height | 60mm (including backing plate, can be customized) |

Fixed work stress | Negative pressure≥-0.095Mpa |

Total power | Without opening the bottom heating 22kw, bottom heating 7.2kw each side |

Actual power consumption | ~9kW/h |

?

Cut sample