- HOME

- Products

- Panel furniture production line

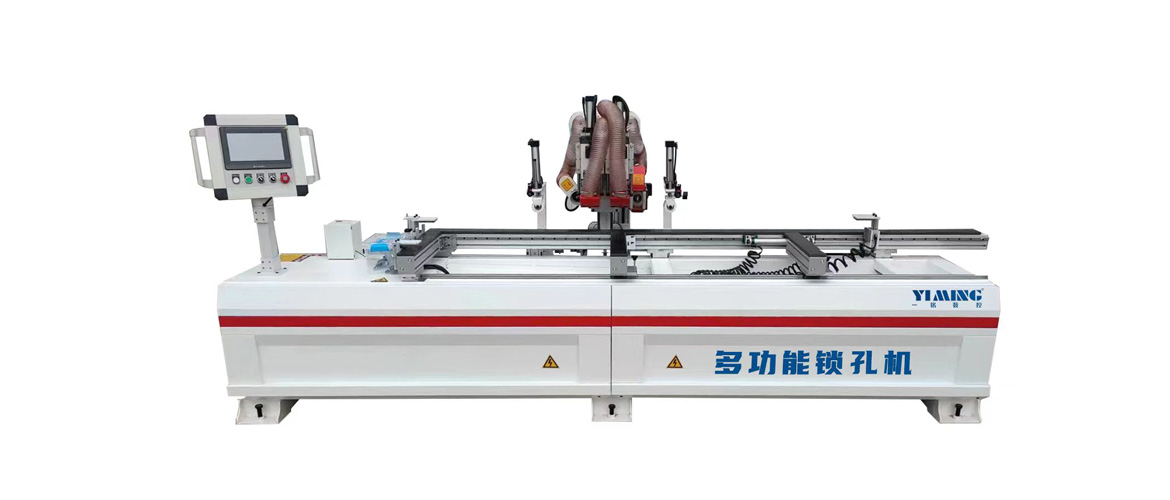

- Multifunctional CNC hole locking machine

CNC cutting machine for thermal insulation materials

Functional characteristics

? | |||

Fuselage specification | 3600*1300*1450mm | Working height | 750mm |

Spindle motor power | T1 upper hole spindle 3.5kw | Spindle motor brand | SCS/Oakmond |

T2 upper milling groove spindle 3.5kw | Spindle motor speed | 18000r/min | |

T3 side milling groove spindle 6.0kw | servo motor | Mitsubishi Pure Servo | |

T4 side repair spindle 3.5kw | Drive motor power | 1000W * 3 (Z-axis with band brake) | |

Frequency converter | Beside/Fuling 7.5KW | sensor | NPN light sensing |

Screw rod | Taiwan TBI25 high-precision screw rod | Hole locking machine control system | LLC Motion Control System |

Bearing and bearing seat | NSK/SKF | Central lubrication system | Automatic oil filling pump |

Reducer | Japanese high-precision reducer 10:1 | Main electrical parts | Chint/Schneider |

handpiece | Aviation aluminum profiles | cable | Shanghai Yichu High Flexible Double Sheath |

Gantry column | High strength Q460 | guide | Taiwan Shangyin 25 square guide rail |

bed frame | Aging treatment of heavy bed | rack | Jueli grinding rack |

Electrical protection | Under voltage, phase loss, phase sequence, overload protection | Pneumatic Components | Baidi Pneumatic/ADK |

Air source filtration | 20 micron high precision filtration | pinch roller | Double rubber flexible pressing wheel |

mesa | PVC engineering board | drag chain | High toughness nylon drag chain |

Fixation method | Pneumatic jig | Transmission cable layout | Slot type isolation |

Vacuum tube | PU is soft and does not crack in all seasons | vacuum cleaner | 3KW |

Vacuum hood | Factory customized | Empty travel speed | 10-100m/min |

Maximum door panel size (length/width/height) | 2800*1000*70mm | Processing speed | 10-80m/min |

T1 Maximum machining stroke (length/width/height) | 2500*90*70mm | Gas source access | 0.6MPa/8mm diameter gas pipe |

T2 Maximum machining stroke (length/width/height) | 2600*90*70mm | Power access | 4 * 6 square international cable |

T3Maximum machining stroke (length/width/height) | 2700*90*70mm | Power type/total power | 380V/50HZ/15KW |

T4 Maximum machining stroke (length/width/height) | 2400*90*70mm | weight | 2000kg |

Main functions: door leaf lock hole, hinge, hardware mounting hole, slot processing, hinge hole (invisible hinge, multi-layer hinge, etc.), door closer, etc | |||

Simple operation and detailed display

Product video introduction

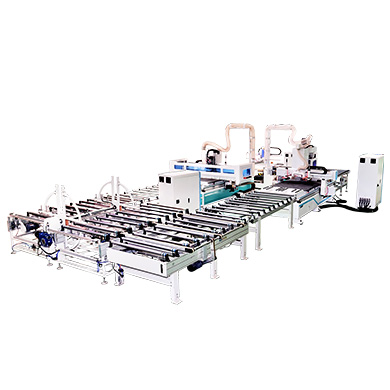

Automatic labeling and loading and unloading processing center

Equipped with a hat type tool magazine, it is a cost-effective automatic loading and unloading machining center.

Automatic feeding, optimized cutting, vertical drilling, and automatic blanking are completed in one step, without interruption in the process, achieving high efficiency output

Cut sample

Let us keep in touch

Your email address will not be published. Required places have been marked *